English

EnglishGrinding

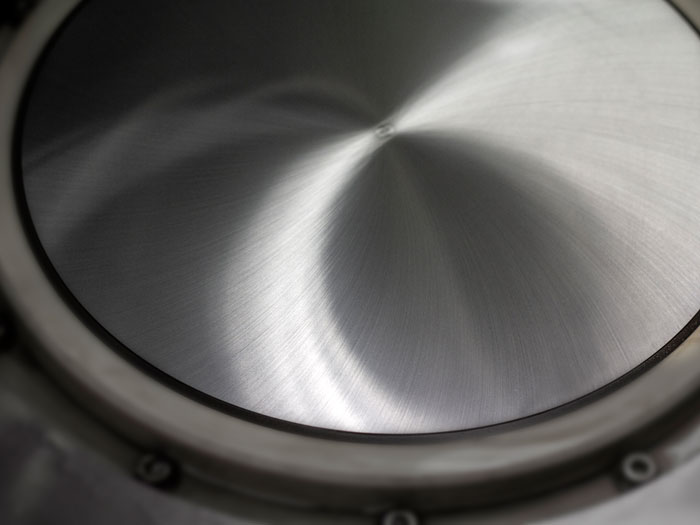

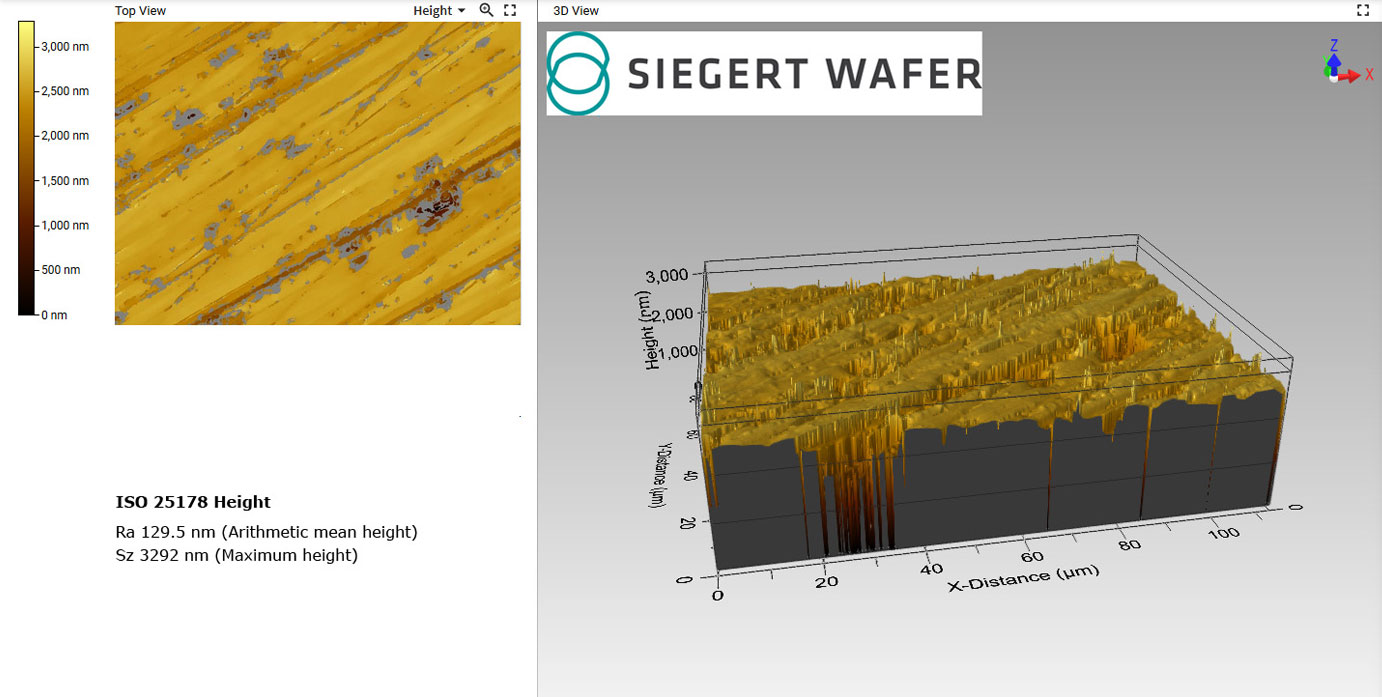

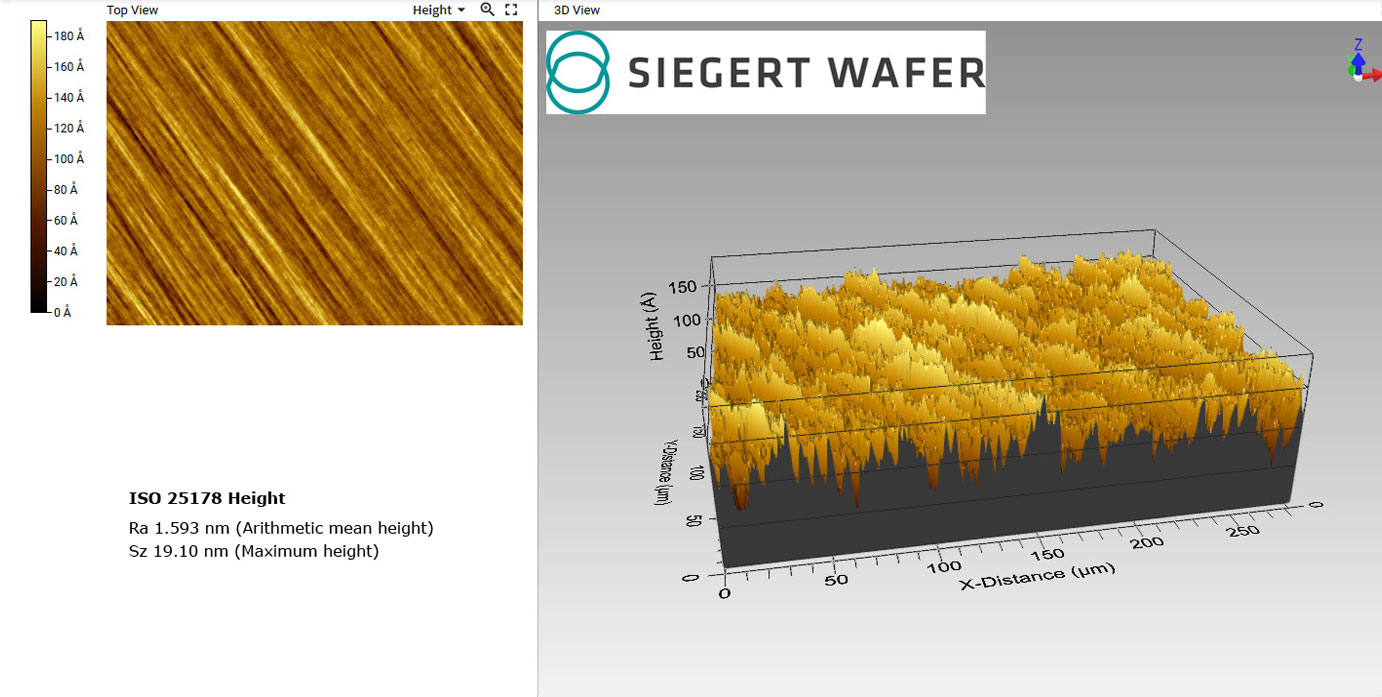

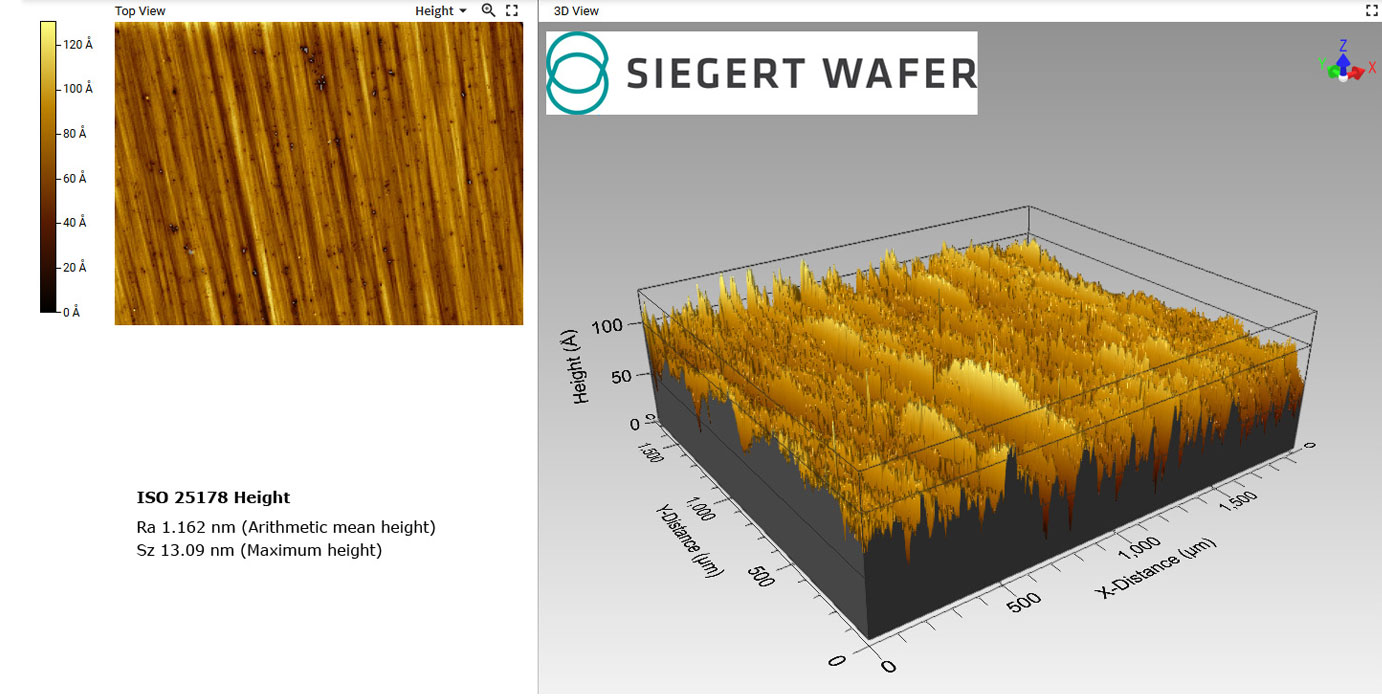

Wafer thinning or grinding is a technology to reduce the wafer thickness. It is also referred as backgrinding or backthinning. Usually it is performed in several steps with different grinding wheels. With each step the grit becomes finer to remove subsurface damage of the previous step and to further reduce surface roughness. The finest Ultrapoligrind wheel leads to a fine ground mirror-like surface.

To protect the wafer front side, it will be temporarily covered with a UV curable grinding tape. The tape can be removed prior shipping out to the customer or it remains on the wafer to protect the surface and prevents breaking during transport.

Wafers can be supplied by the customer or us. Also patterned wafers can be processed. We are specialized in thinning of device layers of SOI Wafers.

Deutsch

Deutsch